格兰u-drill plus大型组合式条播机

格兰u-drill plus 大型条播机—可种肥同施的大型联合式条播机

亮点

- 高速大型条播机(10-18公里/小时)

- 优异的播种性能

- 模块化设计主梁,灵活多变

- 完全与ISOBUS系统兼容

- 操作简单,维护简易

描述

格兰u-drill plus大型条播机,分为一体式和折叠式机架,工作幅宽为3.0米,4.0米,6.0米。该机型可一次完成种床准备、土壤平整和合墒、播种、施肥、镇压等高效作业,性能好,效率高。

Plus代表种肥同施的型号,可播种谷物,同时可施肥。 也可以同时播种两种作物。设备内部有两套播种系统,分别位于两个分开的种箱里。

为了更好地平衡和缩短生长时间,磷肥的施用有利于作物初期的萌芽和生长。 据春季期间的播种及后期的统计,种肥同施可增产25%左右。

此外,现代的农业较以前更为灵活,有时农场主会同时播种两种作物。这种播种方法越来越受欢迎。在第一种作物开始收获时,第二种作物仍在继续生长。

根据工作幅宽,种箱容积有3000升和4350升可选。其中一体式机架的种箱可分成两个部分,分别配备播种轮,分开两部分的比例为40:60。

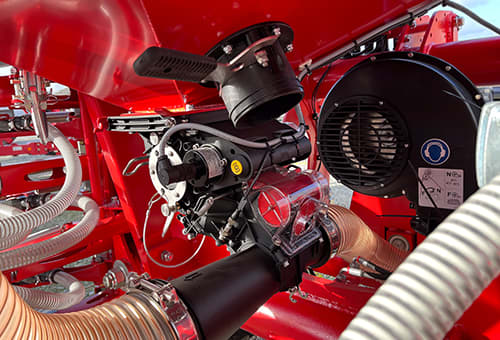

格兰u-drill plus可进行种肥同施作业,作业速度可达15公里/小时,400公斤/公顷。种箱加压装置可确保播种机在各种严苛的条件下性能稳定。

优势

- 高速播种(10-18公里/小时)

- 优异的播种精度

- 模块化设计的机架可根据用户的要求进行调整

- ISOBUS完全兼容

- 操作简易,维修方便

- 地头自动控制管理系统

特征

特征

Step 1: Level the soil

For the best possible preparation, the front tyre packer levels the soil, crushes large clods and thus paves the way for the optimum depth control of the following tools. The front tyre packer has a diameter of 800mm. When it is not needed, it can be lifted hydraulically, simply by pushing a button..

Step 2: Prepare the seedbed

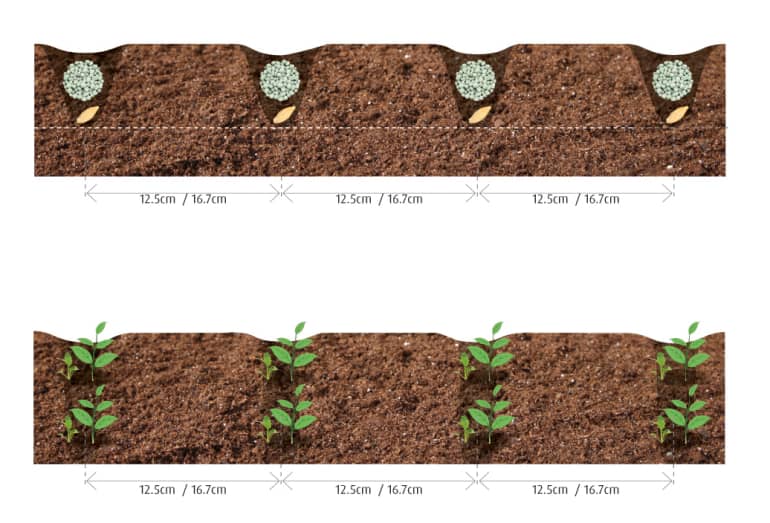

The disc harrow section consists of two rows of aggressively pitched conical discs. The discs are 5mm thick and hardened for long life. Thanks to their conical shape, the cutting angle remains constant. The high rotation speed ensures an excellent cutting quality over the entire working width. The distance between the sowing rows can be 12.5or 16.7cm.

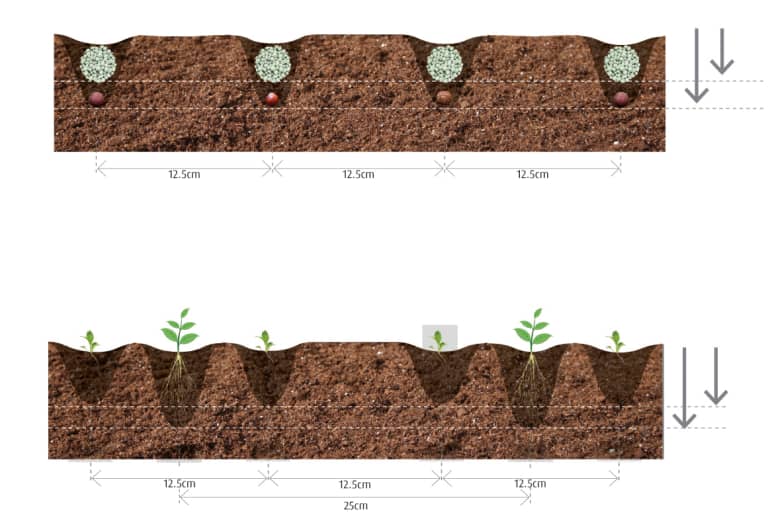

The MD disc section consists of two rows of straight waved discs. The MD disc have been designed for vertical penetration through the flutes. The blade keeps turning, penetrating and cutting even in the most challenging conditions. A seedbed is created only in stripes of 3 to 5 cm in width, in which the seed is placed by the CD coulter.

The MD disc section is available for machines with 16.7 cm row distance and with the u-drill plus in combination with double entry fertiliser injection.

Step 3: First pack, then seed

For perfect depth control of the coulters and an optimum seed-to-soil contact providing excellent capillary action, the loosened soil is re-compacted by a large tyre packer. The large tyre diameter of 900mm significantly reduces the tractive power required by the machine and thus ensures a consistently good work result.

Step 4: Drill and pack at constant seeding depth

The narrow profile of the coulters with their slightly offset steel discs allow easy penetration into the soil. Thus, little pressure is required at this point with only little soil being displaced. The coulter pressure of 100kg can, therefore, be primarily used for the pressing by the integrated press wheels. The result: a uniform seeding depth even at high working speeds! The seeding depth and the coulter pressure can be centrally controlled by the push of a button from the tractor cab – this saves additional time.

The stable depth control and the pressing of the seed produce a capillary system in the soil that ensures access to water and excellent germination

Step 5: Closing

Harrowing the soil completes the drilling. S-shaped or finger harrows ensure an optimum covering of the seeds. The working intensity can be set by the stepless pressure adjustment and at three different angles. To prevent damage to the harrow when reversing, it is equipped with an effective reversing device.

The u-drill comes with a fully automated headland management system. This saves the driver lots of time and eases the operation. Using just one button, the driver can initiate a headland sequence with wheels, discs and coulter bar all capable of automatic operation in timed stages. The lifting sequence starting with the disc section ensures a constant depth control until the headland.

As the headland sequence starts, the metering device stops automatically – avoiding double seeding. The seed hoses are empty at the headland. This saves up to 5% of seed.

The driver can concentrate on steering the machine and the correct operation. In addition double and/or missed seeding is prevented. With headland management the job can be done more quickly, precisely and efficiently. The drill requires only one double-acting spool to operate.

- ELDOS is electric driven by e-bas and e-com, the e-com edition is fully ISOBUS compatible, e-bas works as stand alone controlled system.

- GEOCONTROL by GPS signal is possible which avoids double seeding.

- Special sensors ensure functionality from the tractor cab.

- Five standard rotors are delivered: for fine and large seeds or fertiliser.

- The exchange of the rotors is quickly and easily done without any tools.

- Application rates from 1 to 400kg/ha are possible (depending on working speed and width).

- The metering device is always easily accessible.

Calibration

- Very simple calibration test due to the separate seed guidance.

- A remote control allows the driver to operate the calibration process at the metering device.

- No gear has to be adjusted. The driver simply enters the desired values into the terminal, presses one button to start at the metering device and that’s it.

- The calibration is done automatically.

- A calibration flap with an integrated gate prevents any seed from dropping into the hose.

The u-drill plus has been designed for precise fertiliser placement whilst sowing. It is able to apply fertiliser rates up to 400kg/ha (depending on speed and width). The pressurised hopper system of the 6.0m version ensures that these rates are maintained even under the most difficult conditions. Depending on the individual agronomic requirements, the fertiliser can be applied either directly in the seeding row or in between two rows.

Fertiliser placement within the disc harrow section

The outlets within the second row of the disc harrow section apply the fertiliser exactly in between two sowing rows. All plants have exactly the same distance to the incorporated fertiliser placed. By adjusting the working depth of the disc harrow, the depth of the fertiliser placement is determined.

Fertiliser placement within the seeding row

The fertiliser application within the seeding row is done by the double-entry CD coulter. The fertiliser is placed together with the seeds. This is especially suitable for phosphoric fertiliser in order to support the initial germination and development of the plants in the most efficient way.

Sowing of two different crops

The special design of the double-entry CD coulter with two exits also allows the sowing of two different crops in just one working pass.